Removal and Installation

20. Connect wires to neutral start safety switch.

21.

Connect tan/blue wire to fluid temperature

switch.

NOTICE

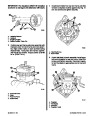

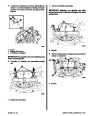

The following procedure describes removal

of transmission without removing engine. If

engine must be removed, refer to Section 2

(see “Table of Contents”).

22.

23.

Connect fluid cooler hoses to transmission.

Connect and adjust shift cable(s) as outlined in

Section 2C - “MIE Models - Velvet Drive Trans-

missions.”

1.

2.

3.

4.

5.

Drain transmission fluid.

IMPORTANT: Velvet Drive Transmission Warran-

ty is jeopardized if the shift lever poppet ball or

spring is permanently removed, if the shift lever

isrepositionedorchangedinanymanner,orifre-

mote control and shift cable do not position shift

lever exactly as shown.

Disconnect fluid cooler hoses.

Disconnect shift cable.

Disconnect wires from neutral start safety switch.

Disconnect TAN/BLUE wire from fluid tempera-

ture switch.

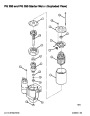

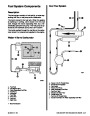

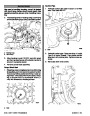

F – N – R

a

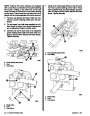

6.

7.

8.

Disconnect propeller shaft coupling.

Remove four rear mount (to engine bed) bolts.

d

Support rear part of engine with either a hoist or

by using wooden blocks under flywheel housing.

b

F

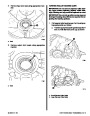

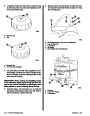

9.

Remove two center transmission-to-flywheel

housing attaching bolts and install two long

studs.

R

IMPORTANT: These two long studs will help sup-

port weight of transmission during removal and

installation.

c

72601

a - Transmission Shift Lever

10.

11.

12.

Remove remaining transmission attaching bolts.

Pull transmission straight back and off engine.

b - Shift Lever Must Be Over This Letter when Propelling Boat

FORWARD

c - Shift Lever Must Be Over This Letter when Propelling Boat

in REVERSE

d - Poppet Ball Must Be Centered in Detent Hole for Each

F-N-R Position (Forward Gear Shown)

Before installing transmission, check transmis-

sion pump indexing for correct rotation. Refer to

“Pump Indexing.”

24.

25.

Refer to Section 2C - “MIE Models - Velvet Drive

Transmissions” and check engine final alignment

as outlined.

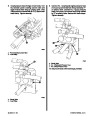

13.

14.

Check transmission output shaft rolling torque.

See “Specifications.”

Apply Quicksilver Engine Coupler Spline Grease

to transmission input shaft splines and engine

drive plate splines.

After engine has been properly aligned, connect

propeller shaft coupler to transmission output

flange. Attach couplers together with bolts, lock-

washers and nuts. Torque to 50 lb. ft. (68 N·m).

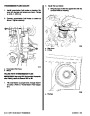

15.

If removed, install rear engine mounting brackets

(to transmission) as outlined in Section 3 (see

“Table of Contents”). Torque to 45 lb. ft. (61 N·m).

26.

27.

Refill transmission with specified fluid. Refer to

“Filling Transmission.”

16.

17.

18.

Align transmission splines with drive plate

splines.

Check for leaks and check fluid level after first en-

gine start-up.

Slide transmission into place and secure with

bolts.

Remove two long studs (installed in Step 9) and

install remaining two bolts. Torque all bolts to 50

lb. ft. (68 N·m).

19.

Relieve hoist tension and fasten rear engine

mounts to engine bed. Tighten bolts securely.

index

90-823224--2 796

VELVET DRIVE IN-LINE TRANSMISSION - 8A-7

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you