Diagnostic Information

damaged. Always use jumper wires with the corre-

sponding mating terminals between connectors for

circuit checking. NEVER probe through connector

seals, wire insulation, secondary ignition wires,

boots, nipples or covers.

The diagnostic charts and functional checks in this

manual are designed to locate a faulty circuit or com-

ponent through logic based on the process of elimi-

nation. The charts are prepared with the require-

ment that the system functioned correctly at the

time of assembly and that there are no multiple

failures.

Microscopic damage or holes will result in eventual

water intrusion, corrosion and/or component or cir-

cuit failure.

WIRE REPAIR

Wiring Harness Service

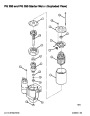

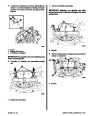

1.

2.

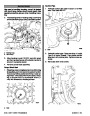

Locate damaged wire.

Marine engine control circuits contain many special

design features not found in standard land vehicle

wiring. Environmental protection is used extensively

to protect electrical contacts and proper splicing

methods must be used when necessary.

Remove insulation as required.

73048

3.

4.

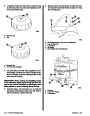

Splice two wires together using splice clips and

rosin core solder.

The proper operation of low amperage input/output

circuits depends upon good continuity between cir-

cuit connectors. It is important before component re-

placement and/or during normal troubleshooting pro-

cedures that a visual inspection of any questionable

mating connector is performed. Mating surfaces

should be properly formed, clean and likely to make

proper contact. Some typical causes of connector

problems are listed below.

73048

Cover splice with heat shrink sleeve to insulate

from other wires.

1.

2.

3.

4.

Improperly formed contacts and/or connector

housing.

73048

Damaged contacts or housing due to improper

engagement.

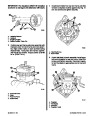

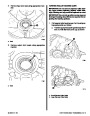

Wiring Connector Service

Corrosion, sealer or other contaminants on the

contact mating surfaces.

Most connectors in the engine compartment are pro-

tected against moisture and dirt which could create

oxidation and deposits on the terminals. This protec-

tion is important because of the very low voltage and

current levels found in the electronic system. The

connectors have a lock which secures the male and

female terminals together. A secondary lock holds

the seal and terminal into the connector.

Incomplete mating of the connector halves dur-

ing initial assembly or during subsequent trouble-

shooting procedures.

5.

Tendency for connectors to come apart due to

vibration and/or temperature cycling.

6.

7.

Terminals not fully seated in the connector body.

Inadequate terminal crimps to the wire.

When diagnosing, open circuits are often difficult to

locate by sight because oxidation or terminal mis-

alignment are hidden by the connectors. Merely wig-

gling a connector on a sensor or in the wiring harness

may locate the open circuit condition. This should al-

ways be considered when an open circuit or failed

sensor is indicated. Intermittent problems may also

be caused by oxidized or loose connections.

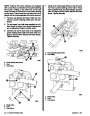

Wire harnesses should be replaced with proper part

number harnesses. When signal wires are spliced

into a harness, use the same gauge wire with high

temperature insulation only.

With the low current and voltage levels found in the

system, it is important that the best possible bond be

made at all wire splices by soldering the splices, as

shown in the following illustrations. Use care when

probing a connector or replacing connector termi-

nals. It is possible to short between opposite termi-

nals. If this happens, certain components can be

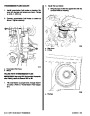

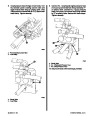

Before making a connector repair, be certain of the

type of connector. Some connectors look similar but

are serviced differently. Replacement connectors

and terminals are listed in the Parts Catalog.

Ensure that the connector seals are not deformed or

crushed when mating the connectors together.

Index

5C-2 - ELECTRONIC FUEL INJECTION (MULTI-PORT AND THROTTLE BODY)

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you