Installation

Checking Clearances

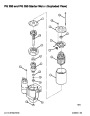

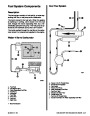

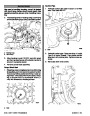

1.

Apply Quicksilver Perfect Seal to engine block/

seal mating surface. Apply grease to seal lips.

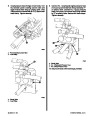

To obtain accurate measurements while using Plasti-

gage, or its equivalent, engine must be out of the boat

and upside down so crankshaft will rest on the upper

bearings and total clearance can be measured be-

tween lower bearing and journal.

2.

Install seal using rear main seal installer or suit-

able device.

To assure the proper seating of the crankshaft, all

bearing cap bolts should be at their specified torque.

In addition, preparatory to checking fit of bearings,

the surface of the crankshaft journal and bearing

should be wiped clean of oil.

IMPORTANT: Inspect bearing caps for orienta-

tion marks prior to removal. If no markings exist,

make suitable marks before disassembly so that

they can be reinstalled in their original locations.

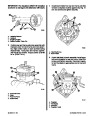

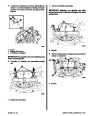

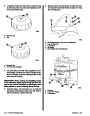

1.

With the oil pan and oil pump removed, make

suitable marks, if required, on bearing cap(s) to

be inspected. Remove bearing cap(s) as

needed. Wipe oil from journal and bearing cap to

be inspected.

a

72356

2. Place a piece of gauging plastic the full width of

the bearing (parallel to the crankshaft) on the

journal as shown.

a - Suitable Device Shown (Rear Main Seal Installer (J-38841)

Not Shown

IMPORTANT: Do not rotate the crankshaft while

the gauging plastic is between the bearing and

journal.

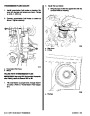

Main Bearings

IMPORTANT: Before removing main bearing

caps or connecting rod caps, mark them for reas-

sembly in their original locations.

a

Main bearings are of the precision insert type and do

not use shims for adjustment. If clearances are found

to be excessive, a new bearing, both upper and lower

halves, will be required. Service bearings are avail-

able in standard size and .001 in., .002, .010 in. and

.020

in. undersize.

Inspection

In general, the lower half of the bearing (except No.

1

bearing) shows a greater wear and the most dis-

tress from fatigue. If, upon inspection, the lower half

is suitable for use, it can be assumed that the upper

half is also satisfactory. If the lower half shows evi-

dence of wear or damage, both upper and lower

halves should be replaced. Never replace one half

without replacing the other half.

b

72558

a - Gauging Plastic

b - Journal

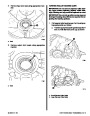

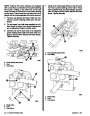

3.

Install the bearing cap and evenly torque the re-

taining bolts to specifications. Bearing cap MUST

be torqued to specification in order to assure

proper reading. Variations in torque affect the

compression of the plastic gauge.

Index

90-823224--2

796

454 CID (7.4L) / 502 CID (8.2L) - 3A-45

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you