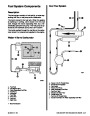

Filling Closed Cooling

Section

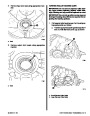

5. Continue filling closed cooling section until cool-

ant level is 1 in. (25 mm) below filler neck.

!

CAUTION

Avoid seawater pickup pump impeller damage

and subsequent overheating damage to stern

drive unit. DO NOT operate engine without water

being supplied to seawater pickup pump.

Fresh Water Flow Thru Exhaust

Manifold

NOTICE

!

CAUTION

See “Specifications” for approximate

closed cooling system capacity and cool-

ant recommendation.

Models with belt drive seawater pickup pump

must be in the water when running engine be-

cause garden hose will not supply enough water

to system at higher RPM.

6.

7.

8.

9.

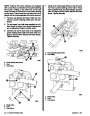

With pressure cap off, start engine and run at fast

idle (1500-1800 RPM). Add coolant solution to

heat exchanger, as required, to maintain coolant

level 1 in. (25 mm) below filler neck.

!

WARNING

Do not remove coolant cap when engine is hot.

Coolant may discharge violently.

After engine has reached normal operating tem-

perature (thermostat is fully open), and coolant

level remains constant, fill heat exchanger to bot-

tom of filler neck.

!

CAUTION

Alcohol or Methanol based antifreeze or plain

water are not recommended for use in fresh wa-

ter section of cooling system at any time.

Observe engine temperature gauge to make

sure that engine operating temperature is nor-

mal. If gauge indicates excessive temperature,

stop engine immediately and examine for cause.

!

CAUTION

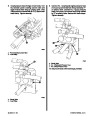

Front of engine should be higher than rear to

purge trapped air out of the system during initial

filling. This will minimize the possibility of air be-

ing trapped in the closed cooling section which

can cause engine to overheat.

Install pressure cap on heat exchanger.

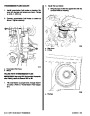

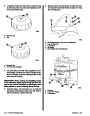

10. Remove cap from coolant recovery reservoir and

fill to FULL mark with coolant solution. Reinstall

cap.

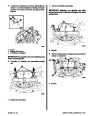

1.

Remove coolant cap on heat exchanger.

11.

With engine still running, check hose connection,

fittings and gaskets for leaks. Repeat Step 4.

IMPORTANT: Engine overheating is often due to

air being trapped in closed cooling section.

Purge air by running engine at 2000 RPM for 10

minutes.

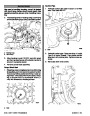

a

!

WARNING

Allow engine to cool before removing pressure

cap. Sudden loss of pressure could cause hot

coolant to boil and discharge violently. After en-

gine has cooled, turn cap 1/4 turn to allow any

pressure to escape slowly, then push down and

turn cap all the way off.

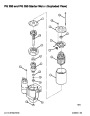

71518

a - Hex Head Bleeder

12.

Recheck coolant level after first open-throttle

boat test and add coolant, if necessary.

2.

3.

Open hex bleeder on thermostat.

Fill closed cooling system with coolant mixture

through heat exchanger fill neck until coolant ap-

pears at bleeder valve.

13.

Maintain coolant level in coolant recovery reser-

voir between ADD and FULL marks with engine

at normal operating temperature.

4.

Close bleeder securely.

Index

90-823324--2 796

CLOSED COOLING SYSTEMS - 6B-15

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you