3.

If cylinders have less than .005 in. (0.127 mm) ta-

per or wear, they can be conditioned with a hone

and fitted with high limit standard size piston. A

cylinder bore of more than .005 in. wear or taper

maynotcleanupentirelywhenfittedtoahighlim-

it piston. To entirely clean up the bore, it will be

necessary to bore for an oversize piston. If more

than .005 in. taper or wear, bore and hone to

smallest oversize that will permit complete resur-

facing of all cylinders.

4.

When pistons are being fitted and honing is not

necessary, cylinder bores may be cleaned with a

hot water and detergent wash. After cleaning,

swab cylinder bores several times with light en-

gine oil and a clean cloth, then wipe with a clean

dry cloth.

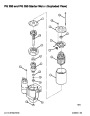

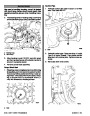

72569

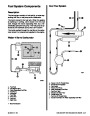

Measuring Cylinder Bore

8.

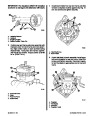

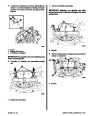

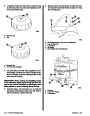

Check cylinder head gasket surfaces for war-

page with a machinist’s straight-edge and a feel-

er gauge, as shown. Take measurements diago-

nally across surfaces (both ways) and straight

down center. If surfaces are warped more than

CYLINDER BORING

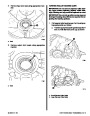

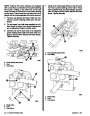

1. Before using any type boring bar, file off top of cyl-

inder block to remove dirt or burrs. This is veryim-

portant to prevent boring bar tilt, with result that

bored cylinder wall is not at right angles to crank-

shaft.

.003

mm) overall, block must be resurfaced by an au-

tomotive machine shop.

in. (0.07 mm) in a 6 in. area or .007 in. (0.2

2.

Measure piston to be fitted with a micrometer,

measuring at center of piston skirt and at right

angles to piston pin. Bore cylinder to same diam-

eter as piston and hone to give specified clear-

ance.

a

NOTE:Hone cylinders as outlined under “Cylinder

Honing” and “Piston Selection,” following.

3.

Carefully observe instructions furnished by man-

ufacturer of equipment being used.

CYLINDER HONING

b

72566

1.

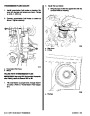

Follow hone manufacturer’s recommendations

for use of hone and cleaning and lubrication dur-

ing honing.

a - Machinist’s Straight Edge

b - Feeler Gauge

2.

Occasionally, during the honing operation, thor-

oughly clean cylinder bore and check piston for

correct fit in cylinder.

CYLINDER CONDITIONING

1.

Performance of the following operation depends

upon engine condition at time of repair.

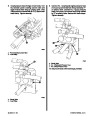

3. When finish-honing a cylinder bore to fit a piston,

move hone up and down at a sufficient speed to

obtain very fine uniform surface finish marks in a

crosshatch pattern of approximately 30 degrees

to cylinder bore. Finish marks should be cleanbut

not sharp, free from imbedded particles and torn

or folded metal.

2.

If cylinder block inspection indicates that block is

suitable

for

continued

use

(except

for

out-of-round or tapered cylinders), they can be

conditioned by honing or boring.

4.

Permanently mark piston (for cylinder to which it

has been fitted) and proceed to hone cylinders

and fit remaining pistons.

Index

90-823224--2

796

454 CID (7.4L) / 502 CID (8.2L) - 3A-61

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you