Knock Control Module

IMPORTANT: If there is abnormal mechanical en-

gine noise (rattles or knocks), they may give a

falseknockretardsignal.Iffueloctaneistoohigh

or too low, a false signal can also be sent.

The Knock Control Module contains solid state cir-

cuitry which monitors the knock sensor’s AC voltage

signal and then supplies an 8-10 volt signal, if no

spark knock is present, to the Ignition Control Mod-

ule. If spark knock is present, the Knock module will

remove the 8-10 volt signal to the Ignition Control

Module.

TESTING KNOCK MODULE AND SENSOR

NOTE: A digital volt-ohmmeter (DVOM) and an un-

powered test light (low power test light - 300mA or

less) are needed to conduct the following test.

a

b

!

WARNING

Avoid fire or explosion. Ensure that engine

compartment is well ventilated and gasoline va-

pors are not present when performing electrical

tests inside the engine compartment. Sparks

generated by electrical tests could ignite gaso-

line vapors causing fire or explosion.

1.

2.

Start engine and warm it up to normal operating

temperature.

c

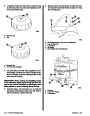

Connect the positive (+) lead from the DVOM to

the PURPLE/WHITE timing terminal that comes

fromtheengineharness(seepreviouswiringdia-

gram). Connect the negative (–) lead from the

DVOM to a good engine ground (–). With the en-

gine running, there should be 8-10 volts on this

circuit. If voltage is not present, check to ensure

that there is 12 volts to the knock module (PUR-

PLE wire Terminal “B”).

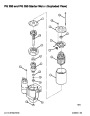

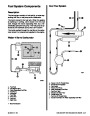

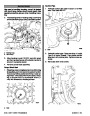

Knock Sensor System

a - Positive Lead (12 Volts)

b - 8-10 Volts To Knock Sensor

c - Knock Sensor

It is extremely important that the correct knock mod-

ule and sensor be used for the engine application.

Using an incorrect knock module or sensor will result

in unrecognized spark knock and engine damage.

The Knock module terminal B is powered by 12 volts

from the ignition switch. If the 12 volt power source

isnotpresent,theknockmodulecannotsendan8-10

volt signal to the ignition control module and a false

constant spark retard will result.

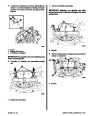

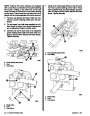

3. Advance the throttle to approximately 1500RPM.

4.

Disconnect the harness connector (BLUE wire)

from the knock sensor. Connect the unpowered

test light to a positive (+) 12 volt source. To simu-

late an AC voltage, rapidly tap the knock sensor

harness terminal with the test light. If knock mod-

ule and wiring is functioning properly, you should

seeavoltagedropontheDVOM.Ifavoltagedrop

is not seen, check the BLUE wire from the sensor

to the knock module for a short or open circuit. If

the circuit is functioning properly to this point, the

knock sensor may not be functioning. Proceed to

the following step.

Terminal “E” of the knock module is the signal line

from the knock sensor. If this circuit opens or shorts

to ground, the knock module will never remove the

8-10

volt signal from terminal “C” to and no spark re-

tard will occur. The ground circuit for the knock mod-

ule is connected to terminal “D”. If the ground circuit

opens, the knock module will not be able to remove

the 8-10 volt signal and spark knock cannot be con-

trolled.

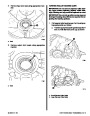

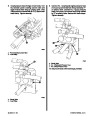

5.

6.

Reconnect the knock sensor harness connector

to the sensor.

IMPORTANT: If knock sensor wire is routed too

close to secondary ignition wires, the Knock

module may see the interference as a knock sig-

nal, resulting in false timing retard.

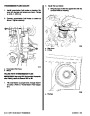

While still watching the DVOM, lightly and rapidly

tap on the engine block near the knock sensor

with a small hammer. If the knock sensor is func-

tioning properly, you should see the voltage de-

crease. If a voltage drop is not seen, the knock

sensor is faulty.

Index

90-823224--2 796

IGNITION SYSTEM - 4B-21

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you