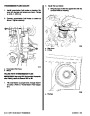

Hydraulic valve lifters require little attention. Lifters

are extremely simple in design. Normally, readjust-

ments are not necessary and servicing requires only

that care and cleanliness be exercised in the handl-

ing of parts.

In most cases, where noise exists in one or more lift-

ers, all lifter units should be removed, disassembled,

cleaned in solvent, reassembled and reinstalled in

engine. If dirt, corrosion, carbon, etc., is shown to ex-

ist in one unit, it more likely exists in all the units; thus

it would only be a matter of time before all lifters

caused trouble.

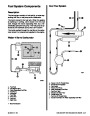

Locating Noisy Lifters

Locate a noisy valve lifter by using a piece of garden

hose approximately 4 ft. (1.2 m) in length. Place one

end of hose near end of each intake and exhaust

valve, with other end of hose to the ear. In this man-

ner, sound is localized, making it easy to determine

which lifter is at fault.

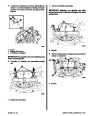

Removal

IMPORTANT: Keep push rod and hydraulic valve

lifter from each valve together as a matched set

and mark them so they can be reinstalled in the

same location later.

Another method is to place a finger on face of valve

spring retainer. If lifter is not functioning properly, a

distinct shock will be felt when valve returns to its

seat.

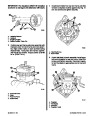

Remove as outlined:

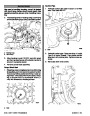

1. Remove rocker arm covers.

2. Remove intake manifold.

General types of valve lifter noise are as follows:

1.

Hard rapping noise - usually caused by plunger

becoming tight in bore of lifter body so that return

spring cannot push plunger back up to working

position. Probable causes are:

3. Remove rocker arm assemblies and push rods.

4.

Remove valve lifters.

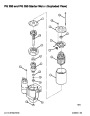

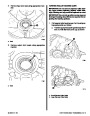

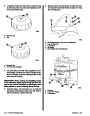

NOTE:Gen VI engines with roller lifters have addi-

tional valve train components shown below.

a. Excessive varnish or carbon deposit, causing

abnormal stickiness.

b

b. Galling or “pickup” between plunger and bore

of lifter body, usually caused by an abrasive

piece of dirt or metal wedged between plung-

er and lifter body.

a

2.

Moderate rapping noise - probable causes are:

a. Excessively high leakdown rate.

b. Leaky check valve seat.

72329

c. Improper adjustment.

a - Lifter Restrictor Retainer

b - Fasteners

3.

4.

General noise throughout valve train - this will, in

most cases, be a definite indication of insufficient

oil supply or improper adjustment.

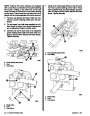

a

Intermittent clicking - probable causes are:

b

a. A microscopic piece of dirt momentarily

caught between ball seat and check valve

ball.

b. In rare cases, ball itself may be out of round

or have a flat spot.

72340

a - Roller Lifter Restrictor

b - Roller Lifter

c. Improper adjustment.

5.

6.

Remove lifter restrictors on roller lifters models.

Remove valve lifters.

Index

90-823224--2

796

454 CID (7.4L) / 502 CID (8.2L) - 3A-25

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you