Cleaning System

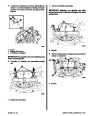

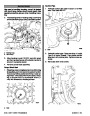

1. Remove seawater drain plug from bottom of heat

exchanger and allow water to drain. After water

has drained completely, coat threads of drain

plug with Quicksilver Perfect Seal and rein-

stall.

Closed Cooling Section

Closed cooling section of closed cooling system

should be cleaned at least once every two years or

whenever decreased cooling efficiency is experi-

enced.

A good grade automotive cooling system cleaning

solution may be used to remove rust, scale or other

foreign material. Always follow manufacturer’s in-

structions for the cleaner.

c

e

a

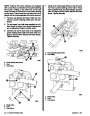

If closed cooling section is extremely dirty, a pressure

flushing device may be used to flush out remaining

deposits. Flushing should be done in direction oppo-

site normal coolant flow to allow water to get behind

deposits and force them out. Refer to instructions

which accompany flushing device for proper hookup

and flushing procedure.

d

b

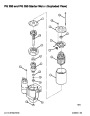

72718

NOTICE

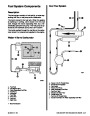

Typical V-8 Engine

For information and procedures for draining

and flushing Seawater Section of Closed

Cooling (Coolant) Models, refer to SECTION

1B. For cold weather or extended storage, re-

fer to SECTION 1B.

a - Bolt

b - End Cap

c - Sealing Washer

d - Gasket

e - Drain Plug

2.

Remove bolts which secure end plates to each

end of heat exchanger, then remove end plates,

seal washers and gaskets. Discard seal washers

and gaskets. Clean gasket material from end

plates and heat exchanger.

Seawater Section

Cooling efficiency of an engine with closed cooling is

greatly dependent upon heat transfer through the

tubes within the heat exchanger. During engine oper-

ation, contaminants within the seawater (such as

salt, silt, lime, etc.) collect on the inside of the tubes,

thus reducing heat transfer and greatly decreasing

heat exchanger efficiency. It is, therefore, recom-

mended that the seawater section of the heat ex-

changer be cleaned at least once every two years or

whenever decreased cooling efficiency is suspected,

as follows:

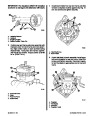

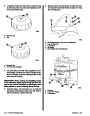

3.

4.

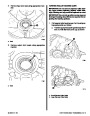

Clean water passages in heat exchanger by in-

serting a suitable size wire brush into each pas-

sage. Use compressed air to blow loose particles

out of water passages.

Apply Quicksilver Perfect Seal to both sides of

new end plate gaskets, then reinstall end plates,

using new gaskets and seal washers. (Be sure to

install seal washers between end plates and gas-

kets.) Torque end plate bolts to specifications.

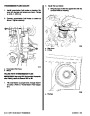

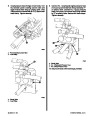

IMPORTANT: It may be necessary to remove heat

exchanger on some models. If heat exchanger is

removed, be sure to refill closed cooling section

with coolant.

!

CAUTION

Avoid seawater pickup pump impeller damage.

DO NOT operate engine without water being

supplied to seawater pickup pump.

5.

With boat in the water and/or cooling water prop-

erly supplied to seawater pickup pump, start en-

gine and inspect for leaks.

Index

6B-14 - CLOSED COOLING SYSTEMS

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you