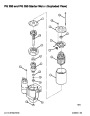

Multi Port Injector Balance Test

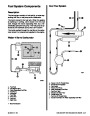

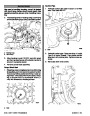

At this point, insert clear tubing attached to vent valve

into a suitable container and bleed air from gauge

and hose to ensure accurate gauge operation. Re-

peat this step until all air is bled from gauge.

(Refer to the following figure for test set-up.)

The injector balance tester is a tool used to turn the

injector ON for a precise amount of time, thus spray-

ing a measured amount of fuel into the manifold. This

causes a drop in fuel rail pressure that we can record

and compare between each injector. All injectors

should have the same amount of pressure drop. Any

injector with a pressure drop that is 1.5 PSI (or more)

greater or less than the average drop of the other in-

jectors should be considered faulty and replaced. In-

jector testers are available for various manufactur-

ers. For 7.4L / 454 and 502 engines: the tester must

be capable of selecting an injector pulse width in the

range of 200-400 milliseconds (m sec). The recom-

mended starting point for these engines is approxi-

mately 300 m sec. In any case a pulse width that

drops the fuel rail pressure to half the normal operat-

ing pressure, should be used.

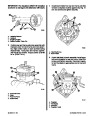

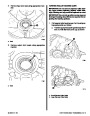

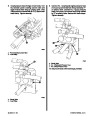

STEP 2

Turn ignition OFF for ten seconds and then ON again

several times to get fuel pressure to its maximum.

Record this initial pressure reading. Energize tester

one time and note pressure drop at its lowest point.

(Disregard any slight pressure increase after drop

hits low point.) By subtracting this second pressure

reading from the initial pressure, we have the actual

amount of injector pressure drop.

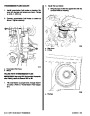

STEP 3

Repeat Step 2 on each injector and compare the

amount of drop. Usually, good injectors will have

virtually the same drop. Retest any injector that has

a pressure difference of 1.5 PSI (10 kPa), either more

or less than the average of the other injectors on the

engine. Replace any injector that also fails the retest.

If the pressure drop of all injectors is within 1.5 PSI

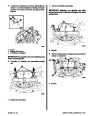

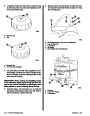

STEP 1

Engine cool down period (ten minutes) is necessary

to avoid irregular readings due to “hot soak” fuel boil-

ing. Relieve fuel pressure in the fuel rail as outlined

in “Fuel Pressure Relief Procedure” in “Repair Proce-

dures.” Remove plenum as outlined in “Repair Pro-

cedures.” With ignition OFF, connect fuel pressure

gauge to fuel pressure tap.

(10

kPa) of this average, the injectors appear to be

flowing properly. Reconnect them and review “Trou-

bleshooting.”

NOTE: The entire test should not be repeated more

than once without running the engine to prevent

flooding.(Thisincludesanyretestonfaultyinjectors.)

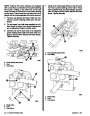

Disconnect harness connectors at all injectors, and

connect injector tester to one injector. Use adaptor

harness furnished with injector tester to energize in-

jectors. Follow manufacturer’s instructions for use of

adaptor harness. Ignition must be OFF at least ten

seconds to complete ECM shutdown cycle. Fuel

pump should run about two seconds after ignition is

turned ON.

Index

5C-34 - ELECTRONIC FUEL INJECTION (MULTI-PORT AND THROTTLE BODY)

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you