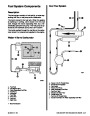

30.

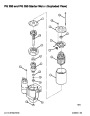

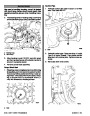

Remove mixture screws.

IMPORTANT: DO NOT use a wire or drill to clean

jets, passages, or tubes in carburetor, as this

may enlarge orifices and seriously affect carbu-

retor calibration.

a

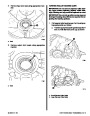

3. Wipe all parts that cannot be cleaned in immer-

sion cleaner with a clean, dry cloth.

4.

Carefully inspect all carburetor parts for damage

or wear; pay particular attention to the following:

a. Idle mixture screws - Replace if damaged or

b

worn.

b. Fuel inlet needle valve and seat - Replace

70467

withnewneedleandseatifwornordamaged.

c. Casting surfaces - Inspect accelerator

pump plunger well for scoring or deposits.

Replace worn or corroded components.

a - Idle Mixture Screw

b - Spring, Idle Mixture Screw

d. All linkage rods and levers - Replace if

Cleaning and Inspection

worn or damaged.

e. Accelerator pump and plunger parts - Re-

place pump and parts if worn or damaged.

!

CAUTION

f.

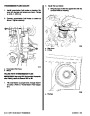

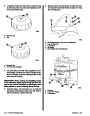

Float assemblyandhingepin-Floatweight

of each should be the same. Replace either

if fuel can be heard inside when shaken.

Check hinge pin and holes for wear. Replace

components if worn or defective.

Rubber, plastic parts, pump plungers or dia-

phragms cannot be immersed in carburetor

cleaner.

!

CAUTION

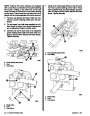

g. Throttle valves and shafts - Check for bind-

ing (through entire operating range, making

sure valves open and close completely) or for

looseness in carburetor body.

Avoid damage to carburetor. Do not leave carbu-

retor in immersion-type cleaner for more than

two hours.

IMPORTANT: DO NOT remove throttle valves. If

any of the throttle parts or float bowl/carburetor

body shaft bores are found to be worn or dam-

aged, carburetor replacement is required.

IMPORTANT: Do not immerse metering rod

springs in carburetor cleaner; the color, if not

“natural” metal, may be removed. Clean

separately as needed.

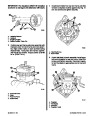

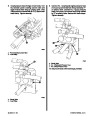

h. Choke valve and shaft/lever assembly -

Check shaft and lever for excessive loose-

ness in air horn. Check choke valve and

shaft/lever assembly for binding through en-

tire operating range. Air horn assembly must

be replaced if choke valve and shaft/lever are

worn.

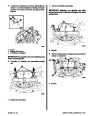

1.

Clean metal carburetor parts in a commercial, im-

mersion-type cleaner, until all deposits have

been removed. Follow manufacturer’s instruc-

tions of cleaner being used for proper cleaning

and rinsing procedures.

!

CAUTION

5.

Check that choke pull-off diaphragm plunger re-

tracts when vacuum is applied to unit, and that it

holds vacuum (plunger remainsseatedifvacuum

is maintained).

Avoid personal injury. Always wear safety

glasses when using compressed air.

2.

Blow out passages with compressed air. Do not

drill through passages.

Index

5B-34 - WEBER 4 BARREL CARBURETOR

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you