Description

Before starting engine each day, check to ensure that

coolant is visible in coolant recovery bottle.

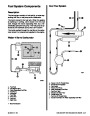

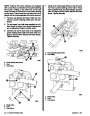

There are several configurations of this cooling sys-

tem, but the operation is essentially identical. Basi-

cally, the system is composed of two separate sub-

systems: the seawater system and the closed

cooling system. The seawater system is similar in

function to the fan used in an automobile because it

absorbs heat (from the closed cooling system) as it

passes through the heat exchanger. The closed cool-

ing system is similar in function to the rest of the cool-

ing system in an automobile.

If coolant is not visible, check fresh water section of

cooling system (including coolant recovery system)

for leaks and repair, as necessary. Refill fresh water

section with recommended coolant solution, as out-

lined under “Changing Coolant,” following.

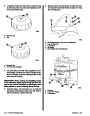

If coolant is visible, start engine and run until it reach-

es normal operating temperature, then recheck cool-

ant level in coolant recovery bottle. Coolant level

MUST BE between the ADD and FULL marks (on

front of bottle).

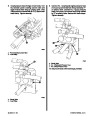

The coolant recovery system keeps the reservoir full.

Normal coolant overflow into recovery bottle is ap-

proximately 1/2 pint (230 mL) during warm-up. The

coolant recovery system draws coolant back into the

reservoir from the recovery bottle as the engine

cools. As long as there is coolant in the recovery

bottle, the reservoir should remain completely full. If

not, there’s a vacuum leak, usually at the hose leav-

ing the reservoir, or the gasket under the recovery fill-

er cap. The gasket seals against the outer rim of the

filler neck.

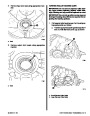

! WARNING

Allow engine to cool before removing pressure

cap, as sudden loss of pressure could cause hot

coolant to boil and discharge violently. After en-

gine has cooled, turn cap 1/4 turn to allow any

pressure to escape slowly, then push down and

turn cap all the way off.

If level is low, remove fill cap from coolant recovery

bottle and add required amount of coolant solution.

Use a 50/50 mixture of ethylene glycol antifreeze and

pure,softwaterforcoolantadditions.Iffrequentaddi-

tions of coolant are required, check fresh water sec-

tion for leaks.

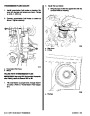

IMPORTANT: The coolant (antifreeze) flows

around the outside of the cooling tubes while

seawater flows through the inside of the cooling

tubes in the heat exchanger.

IMPORTANT: ALCOHOL OR METHANOL BASE

ANTIFREEZE OR PLAIN WATER ARE NOT REC-

OMMENDED FOR USE IN COOLING SYSTEM AT

ANY TIME. In areas where ethylene glycol is not

available, and the possibility of freezing does not

exist, it is permissible to use a solution of rust in-

hibitor and pure, soft water (mixed to manufac-

turer’s recommendations).

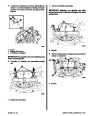

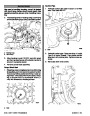

Maintaining Coolant Level

a

Occasionally, check to ensure that coolant recovery

system is functioning properly by removing pressure

capfromheatexchangerandcheckinglevel.Coolant

level should be up to bottom of heat exchanger filler

neck. If low, examine entire fresh water section (es-

pecially coolant recovery system) for leaks and re-

pair, if necessary.

72520

IMPORTANT: When reinstalling pressure cap, be

sure to tighten it until it contacts stops on filler

neck.

Coolant Recovery Bottle

a - Fill Cap

Index

6B-2 - CLOSED COOLING SYSTEMS

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you