4.

5.

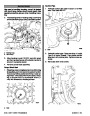

Remove bearing cap. The flattened gauging

plastic will be found adhering to either the bearing

cap or journal.

8. Proceed to the next bearing. After all bearings

have been checked, rotate the crankshaft to see

that there is no excessive drag. When checking

No. 1 main bearing, loosen accessory drive belts

so as to prevent tapered reading with plastic

gauge.

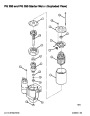

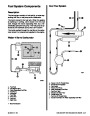

On the edge of the gauging plastic envelope

there is a graduated scale which is correlated in

thousandths of an inch. Without removing the

gauging plastic, measure its compressed width

(at the widest point) with the graduations on the

gauging plastic envelope as shown.

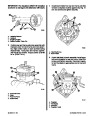

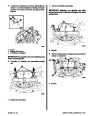

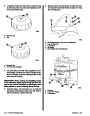

9. Measure crankshaft end play (see “Specifica-

tions”) by forcing the crankshaft to the extreme

front position. Measure at the front end of the rear

main bearing with a feeler gauge as shown.

a

a

b

72557

a - Compressed Gauging Plastic

b - Graduated Scale

72543

a - Measuring Crankshaft End Play - (Force Crankshaft To

Extreme Forward Position )

NOTE:Normally main bearing journals wear evenly

and are not out of round. However, if a bearing is be-

ing fitted to an out-of-round journal (.001 in. max.),

be sure to fit to the maximum diameter of the journal:

If the bearing is fitted to the minimum diameter, and

the journal is out of round .001 in., interference be-

tween the bearing and journal will result in rapid

bearing failure. If the flattened gauging plastic tapers

toward the middle or ends, there is a difference in

clearance indicating taper, low spot or other irregu-

larity of the bearing or journal. Be sure to measure

the journal with a micrometer if the flattened gauging

plastic indicates more than .001 in. difference.

Replacement

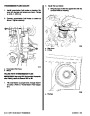

NOTE:Main bearings may be replaced with or with-

out removing crankshaft.

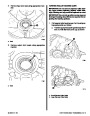

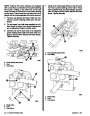

a

b

c

6.

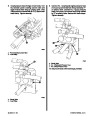

If the bearing clearance is within specifications,

the bearing insert is satisfactory. If the clearance

is not within specifications, replace the insert. Al-

ways replace both upper and lower inserts as a

unit.

72359

Main Bearing Inserts

a - Lower Bearing Insert (Install In Cap)

b - Upper Bearing Insert (Install In Block)

c - Oil Groove

7.

A standard, or .001 in., undersize bearing may

producetheproperclearance.Ifnot,itwillbenec-

essary to regrind the crankshaft journal for use

with the next undersize bearing.

After selecting new bearing, recheck clearance.

Index

3A-46 - 454 C.I.D. (7.4L) / 502 C.I.D. (8.2L)

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you