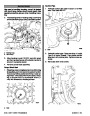

WITH CRANKSHAFT REMOVED

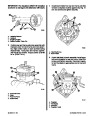

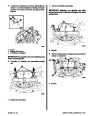

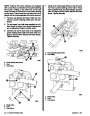

3. Rotate the crankshaft clockwise as viewed from

the front of engine. This will roll upper bearing out

of block.

1.

2.

Remove and inspect the crankshaft as outlined.

Remove the main bearings from the cylinder

block and main bearing caps.

4.

Oil new selected size upper bearing and insert

plain (no notched) end between crankshaft and

indented or notched side of block. Rotate the

bearing into place and remove tool from oil hole

in crankshaft journal.

3.

Coat bearing surfaces of new, correct size, main

bearings with oil and install in the cylinder block

and main bearing caps.

4.

Install the crankshaft.

5. Oil new lower bearing and install in bearing cap.

6.

Install main bearing cap with marks made on dis-

assembly (or arrows, if present) pointing toward

front of engine.

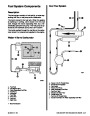

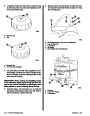

WITHOUT CRANKSHAFT REMOVED

IMPORTANT: Inspect bearing caps for orienta-

tion marks prior to removal. If no markings exist,

make suitable marks before disassembly so that

they can be reinstalled in their original locations.

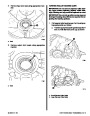

7.

Torque all main bearing caps, EXCEPT THE

REAR MAIN CAP, to 110 lb. ft. (149 N·m). Torque

rear main bearing cap to 10-12 lb. ft. (14-16

N·m); then tap end of crankshaft, first rearward

then forward with a lead hammer. This will line up

rear main bearing and crankshaft thrust sur-

faces. Torque rear main bearing cap to 110 lb. ft.

(149 N·m).

1.

With oil pan, oil pump and spark plugs removed,

make suitable marks on cap and remove cap on

main bearing requiring replacement. Remove

bearing from cap.

2.

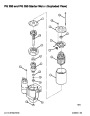

Install main bearing remover/installer in oil hole

in crankshaft journal. If such a tool is not avail-

able,acotterpinmaybebent,asshown,todothe

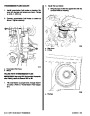

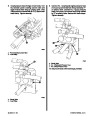

Connecting Rod Bearings

job.

Connecting rod bearings are of the precision insert

type and do not use shims for adjustment. DO NOT

FILE RODS OR ROD CAPS. If clearances are found

to be excessive, a new bearing will be required. Ser-

vice bearings are available in standard size and .001

in. and .002 in. undersize for use with new and used

standard size crankshafts, and in .010 in. and .020 in.

undersize for use with reconditioned crankshafts.

b

Inspection and Replacement

IMPORTANT: Before you remove the connecting

rod cap, mark the side of the rod and cap with the

cylinder number to assure matched reassembly

of rod and cap.

a

72556

a - Main Bearing Remover / Installer (J-8080)

b - Cotter Pin

1. With oil pan and oil pump removed, mark the side

of the rod and cap with the cylinder number and

remove the connecting rod cap and bearing.

2.

Inspect the bearing for evidence of wear and

damage. Do not reinstall a worn or damaged

bearing.

3.

Wipe both upper and lower bearing shells and

crank pin clean of oil.

Index

90-823224--2

796

454 CID (7.4L) / 502 CID (8.2L) - 3A-47

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you