5.

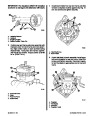

If coupling centerlines are not aligned or if cou-

pling faces are more than .003 in. (0.07 mm) out

of parallel, adjust and retighten engine mounts as

follows:

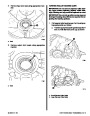

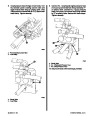

c. After engine has been properly aligned:

Tighten engine mount nuts securely, and be

certain to bend one of the tabs on the tab

washer down onto flat of mount adjusting nut.

Torque clamping screws and nuts to 50 lb. ft.

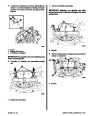

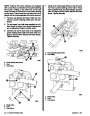

a. TO ADJUST ENGINE UP OR DOWN: Loos-

en locking nut on mounts requiring adjust-

ment and turn both front mount or rear mount

adjusting nuts equally.

(68

N·m).

NOTE: Some rear mounts have only one clamping

screw and nut on each side, instead of the style with

two shown following.

IMPORTANT: Both front mount (or rear mount)

adjusting nuts must be turned equally to keepen-

gine level from side to side.

IMPORTANT: Large diameter of mount trunnion

MUST NOT extend over 3/4 in. (20 mm) from

mount brackets on any of the mounts.

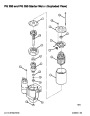

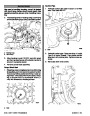

a

d

a

b

e

c

b

c

d

70056

Typical Mount

a - Locking Nut

b - Adjusting Nut

70057

c - Clamping Screws and Nuts, With Lockwashers (Two Each

on Some Models)

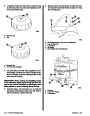

a - Torque Clamping Screw and Nut On All Four Mount Brack-

ets To 50 Lb. Ft (68 N·m)

d - Lag Screws (Or Bolts)

b - Tighten Locking Nut On All Four Mounts Securely

e - Slot Forward (If So Designed - NOT Slotted On This Style

Rear Mount)

c - Bend One Of The Tab Washer Down Onto Flat Of Adjust-

ing Nut

d - Maximum Extension Of Large Diameter Of Trunnion -

3/4

In. (20 mm)

NOTE: Engine mount shown is typical. All models

are similar and adjust in the same manner.

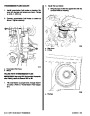

IMPORTANT: All coupler bolts must be Grade 8

(MetricGrade10.9)orbetter,withashoulder(grip

length) long enough to pass through the face

mating plane of couplers.

b. TO MOVE ENGINE TO THE LEFT OR

RIGHT: Loosen clamping screw and nut on

all four mount brackets; move engine to the

left or right as necessary to obtain proper

alignment. On mounts which do have a

slotted hole, a small amount of adjustment

can be obtained with slot on front end of

mounts. Loosen lag screws or bolts (which

fasten mounts to engine bed) and move en-

gine, as required. Tighten lag screws or bolts

securely.

6.

Connect propeller shaft coupler to transmission

output flange. Attach couplers together with

bolts, lockwashers and nuts. Torque to 50 lb.ft.

(68

N·m).

Index

2D-6 –MIE MODELS - HURTH TRANSMISSIONS

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you