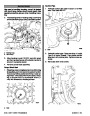

Intake Manifold

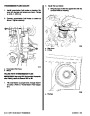

bore. Some of the oil is then used to lubricate cam-

shaft bearings. The remainder of the oil is routed to

the valve lifter oil galleries and No. 1, 2, 3, and 4

crankshaft main bearings by means of individual oil

passages which intersect with the annular grooves.

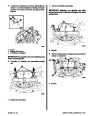

CARBURETED AND THROTTLE BODY

INJECTION

The manifold is of the double level design for efficient

fuel distribution. The upper level of passages feeds

cylinders 2, 3, 5 and 8 while the lower level passages

feed cylinders 1, 4, 6 and 7. All passages are of ap-

proximately equallengthtoassuremoreevenfuel-air

mixture to the cylinders.

The camshaft bearings have holes which align with

the oil passages or annular grooves in the block and

allowoiltoflowin-betweenthebearingsandthecam-

shaft journals. The oil that is forced out the front end

of the No. 1 camshaft bearing drains down onto the

camshaft drive and keeps it lubricated.

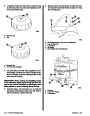

MULTI-PORT INJECTION

The oil which reaches the crankshaft main bearings

is forced through a hole in the upper half of each

bearing and flows in-between the bearings and the

crankshaft journals. Some of the oil is then routed to

the connecting rod bearings through grooves in the

upper half of the crankshaft main bearings and oil

passages in the crankshaft. Oil which is forced out

the ends of the connecting rod bearings and crank-

shaft main bearings is splashed onto the camshaft,

cylinder walls, pistons and piston pins, keeping them

lubricated. Oil which is forced out the front end of the

No.1crankshaftmainbearingalsoassistsinlubricat-

ing the camshaft drive. A baffle plate, mounted on the

bottomofthemainbearingsorintheoilpan,prevents

oil thrown from the crankshaft and connecting rods

from aerating the oil in the oil pan.

The manifold is a cross flow design, with equal length

runners. Injectors are positioned directly above the

intake ports of each cylinder.

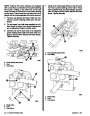

Lubrication System

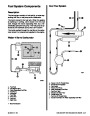

The engine lubrication system is of the force-feed

type in which oil is supplied under full pressure to the

crankshaft, connecting rods, camshaft bearings and

valve lifters, and is supplied under controlled volume

to the push rods and rocker arms. All other moving

parts are lubricated by gravity flow or splash.

A positive displacement gear-type oil pump is

mounted on the rear main bearing cap and is driven

by an extension shaft from the distributor (which is

driven by the camshaft). Oil from the bottom of the

pump in the rear of the oil pan is drawn into the oil

pump through an oil pickup screen and pipe assem-

bly.

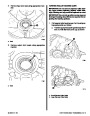

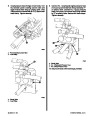

Oil which reaches the valve lifter oil galleries is forced

into each hydraulic valve lifter through holes in the

side of the lifter. From here, the oil is forced through

the metering valve in each of the lifters (which con-

trols the volume of oil flow) and then up through the

push rods to the rocker arms. A hole in each rocker

arm push rod seat allows the oil to pass through the

rocker arm and lubricate the valve train bearing sur-

faces. After lubricating the valve train, oil drains back

to the oil pan through oil return holes in the cylinder

head and block.

If the screen should become clogged, a relief valve

in the screen will open and continue to allow oil to be

drawn into the system. Once the oil reaches the

pump, the pump forces the oil through the lubrication

system. A spring-loaded relief valve in the pump lim-

its the maximum pump output pressure.

Thedistributorshaftandgearalsoislubricatedbythe

oil flowing through the right valve lifter oil gallery.

After leaving the pump, the pressurized oil flows

through a full-flow oil filter. On engines with an engine

oil cooler, the oil also flows through the cooler before

returning to the block. A bypass valve allows oil to by-

pass the filter and oil cooler should they become re-

stricted.

Some of the oil, after leaving the oil cooler and/or fil-

ter, is routed to the No. 5 crankshaft main bearing.

The remainder of the oil is routed to the main oil gal-

lery, which is located directly above the camshaft and

runs the entire length of the block. From the main oil

gallery, the oil is routed through individual oil pas-

sages to an annular groove in each camshaft bearing

Index

90-823224--2

796

454 CID (7.4L) / 502 CID (8.2L) - 3A-17

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you