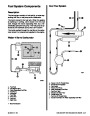

Testing Closed Cooling

System

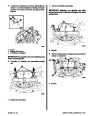

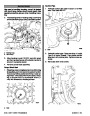

3. Clean inside of filler neck to remove any deposits

or debris. Examine lower inside sealing surface

for nicks or other damage. Surface must be per-

fectly smooth to achieve a good seal between it

and rubber seal on cap. Also check locking cams

on sides of filler neck to be sure that they are not

bent or damaged. If locking cams are bent or

damaged, pressure cap will not hold the proper

pressure.

Testing Coolant for Alkalinity

!

WARNING

Allow engine to cool before removing pressure

cap as sudden loss of pressure could cause hot

coolant to boil and discharge violently. After en-

gine has cooled, turn cap 1/4 turn to allow any

pressure to escape slowly, then push down and

turn cap all the way off.

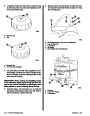

4. Adjust coolant level in fresh water section to 1 in.

(25 mm) below filler neck.

5.

Attach an automotive-type cooling system

pressure tester to filler neck and pressurize

closed cooling section to amount specified in

following chart, based on pressure cap rating for

your engine.

Coolant in fresh water section should be changed ev-

ery two years and should be checked for alkalinity at

least once between change intervals. To check cool-

ant for alkalinity, proceed as follows:

Amount of Pressure

Applied to Closed

Cooling System

Pressure Cap Rating

PSI (110 kPa)

1.

2.

3.

4.

Obtain pink litmus paper from a local supplier

(drug store, pet shop, etc.).

16

20 PSI (138 kPa)

Remove pressure cap from heat exchanger and

insert one end of litmus paper into coolant.

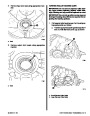

6. Observe gauge reading for approximately two

minutes; pressure should not drop during this

time. If pressure drops, proceed with the follow-

ing steps until leakage is found.

If pink litmus paper turns blue, coolant is alka-

line and need not be replaced.

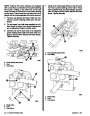

7.

While maintaining specified pressure on closed

cooling section, visually inspect external portion

of cooling system (hoses, gaskets, drain plugs,

petcocks, core plugs, circulating pump seal, etc.)

for leakage. Also listen closely for bubbling or

hissing, as they usually are a sure indication of a

leak.

If pink litmus paper remains pink, coolant is

not alkaline and MUST BE REPLACED, as ex-

plained under “Changing Coolant.”

Pressure Testing System

8.

Refer to “Testing Heat Exchanger” in this section

and test as outlined.

!

WARNING

Allow engine to cool before removing pressure

cap. Sudden loss of pressure could cause hot

coolant to boil and discharge violently. After en-

gine has cooled, turn cap 1/4 turn to allow any

pressure to escape slowly, then push down and

turn cap all the way off.

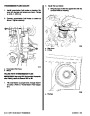

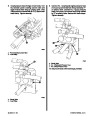

9. If no leakage could be found in above steps, en-

gine is leaking internally, and it probably is due to

one or more of the following: (1) loose cylinder

head bolts or damaged gasket, (2) loose intake

manifold bolts or damaged gasket, (3) loose ex-

haust elbow or distribution block retaining nuts or

damaged gasket, (4) cracked or porous cylinder

head or block, or (5) cracked or porous exhaust

manifold. Proceed as follows until location of in-

ternal leak is found.

If coolant section of closed cooling system is sus-

pected of leaking or not holding sufficient pressure,

and no visible signs of leakage can be found, perform

the following test:

a. Start engine. Re-pressurize system to pre-

viously specified amount and observe pres-

sure gauge on tester. If needle in gauge vi-

brates, compression or combustion is leaking

into closed cooling section from a leak in the

combustion chamber. Exact cylinders, where

leakage is taking place, sometimes can be

found by removing spark plug wires (one at a

time) while observing pressure gauge. Vibra-

1.

Remove pressure cap from heat exchanger or

reservoir.

2.

Clean, inspect and pressure test pressure cap,

as outlined under “Testing Pressure Cap,” to

eliminate the possibility that cap is not maintain-

ing proper pressure in system and is causing

coolant to boil over.

Index

6B-4 - CLOSED COOLING SYSTEMS

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you