Pressure Cap Maintenance

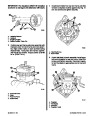

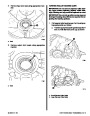

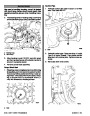

7. Clean sealing surfaces on heat exchanger filler

neck with a cloth. Inspect surfaces for any dam-

age or deposits that may prevent cap from seal-

ing properly.

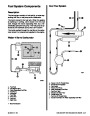

Pressure cap is designed to maintain pressure in

freshwatersectionofclosedcoolingsystemoncethe

engine has attained normal operating temperature.

This raises the boiling point of the coolant, thereby in-

creasing the efficiency of the cooling system. To help

ensure proper operation, cap should be cleaned, in-

spected and pressure tested periodically as follows:

8.

Clean coolant recovery passage in heat ex-

changer filler neck with a wire and blow out with

compressed air.

!

WARNING

a

Allow engine to cool before removing pressure

cap (in next step), as sudden loss of pressure

could cause hot coolant to boil and discharge vi-

olently. After engine has cooled, turn cap 1/4 turn

to allow any pressure to escape slowly, then

push down and turn cap all the way off.

b

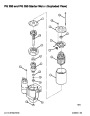

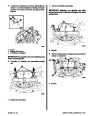

1.

2.

Remove pressure cap from heat exchanger.

Wash cap with clean water to remove any depos-

its or debris from sealing surfaces.

72715

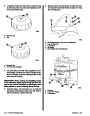

3.

Inspect rubber seal on cap for cuts, cracks or oth-

er signs of deterioration. If seal is damaged, cap

MUST BE replaced.

a - Inspect for Damage

b - Clean Coolant Recovery Passages

9.

Reinstall pressure cap, being sure to tighten until

it contacts stops on filler neck.

4.

5.

Inspect coolant recovery gasket for deterioration

and replace if bad.

Check condition of locking tabs on cap. Replace

cap if tabs are bent or cracked.

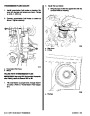

Seawater Pickup Pump

Maintenance

a

c

Whenever insufficient water flow is suspected, sea-

water pickup pump should be disassembled and in-

spected (by an authorized MerCruiser Dealer).

b

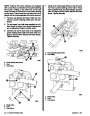

Heat Exchanger Repair

IMPORTANT: Braze with BCUP 2 rod or silver sol-

der. Care must be taken not to melt other joints

during repair.

72714

1.

Internal leaks can be repaired by brazing shut the

ends of the leaking tube. This is only a temporary

fix because usually another tube will start leaking

after a short period of time and this also causes

a reduction in cooling capacity. Do not close more

than three tubes.

a - Rubber Seal (cap MUST BE Replaced If Damaged)

b - Gasket (Look For Cracks Under Gasket)

c - Locking Tabs (1 Hidden)

6.

Refer to “Testing Pressure Cap” and test pres-

sure cap as outlined.

2. Nipples and drains that have been broken off the

heat exchanger can be reattached by brazing.

Index

90-823324--2 796

CLOSED COOLING SYSTEMS - 6B-3

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you