Crankshaft

Cleaning and Inspection

1.

Wash crankshaft in solvent and dry with com-

pressed air.

Removal

2.

Measure main bearing journals and crankpin di-

mensions with a micrometer for out-of-round, ta-

per or undersize (see “Specifications”).

1.

2.

3.

Remove engine from boat.

Drain crankcase oil.

Remove as outlined:

a. Starter.

3.

4.

Check crankshaft for runout (by supporting at

front and rear main bearings journals in V-blocks)

and check at front and rear intermediate journals

with a dial indicator (see “Specifications”).

b. Flywheel housing.

c. Drive coupler/plate and flywheel.

d. Belts.

Replace or recondition crankshaft if not within

specifications.

e. Water pump.

Installation

f.

Crankshaft pulley and torsional damper.

1.

If a new crankshaft is being installed, proceed as

follows:

g. Spark plugs.

h. Oil pan and dipstick tube.

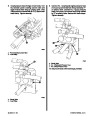

a. Remove timing sprocket or gear from old

crankshaft and reinstall on new crankshaft as

outlined.

i.

j.

Baffle and oil pump.

Timing chain/gear cover.

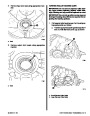

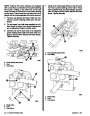

b. Onmodelswithdriveshaftextension,ifoldpi-

lotbushingistobereused,bushingcanbere-

moved without damage by filling pilot bushing

cavity with grease, then inserting an old

transmission input shaft in bore of bushing

and hitting it with a hammer. This will create

hydraulic pressure in pilot bushing cavity

which should force bushing out.

4.

Turn crankshaft to align timing mark with cam-

shaft mark.

5.

6.

Remove camshaft sprocket or gear.

Remove rear main seal.

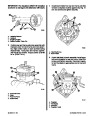

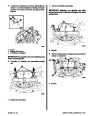

IMPORTANT: Inspect bearing caps for orienta-

tion marks prior to removal. If no markings exist,

make suitable marks before disassembly so that

they can be reinstalled in their original locations.

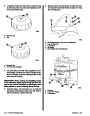

IMPORTANT: Be sure that all bearings and crank-

shaft journals are clean.

7.

Make sure all bearing caps (main and connecting

rods) are marked so they can be reinstalled in

their original locations.

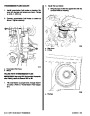

2.

Install main bearings in engine block as follows.

a

8.

Remove connecting rod bearing caps, then push

piston and rod assemblies toward heads.

b

9.

Remove main bearing caps and carefully lift

crankshaft out of cylinder block.

10.

If new main and/or connecting rod bearings are

to be installed, remove main bearing inserts from

cylinder block and bearing caps, and/or connect-

ing rod bearing inserts from connecting rod and

caps. Install new bearings following procedures

outlined.

c

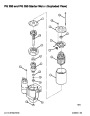

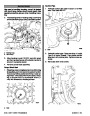

72359

Main Bearing Inserts

a - Lower Bearing Insert (Install In Cap)

b - Upper Bearing Insert (Install In Block)

c - Oil Groove

Index

3A-54 - 454 C.I.D. (7.4L) / 502 C.I.D. (8.2L)

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you