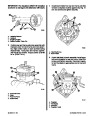

Cleaning and Inspection

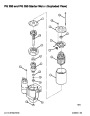

Front Bearing

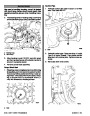

1.

Clean all parts with a clean, soft cloth. Do not use

solvent, or electrical components may be dam-

aged.

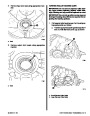

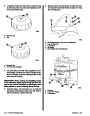

Removal

1.

2.

Remove snap ring.

2.

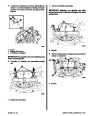

Inspect the following:

Use an arbor press to remove bearing from hous-

ing.

a. Brush Set - Inspect for cracked porcelain

casing, damaged brush leads, poor brush

springs or worn brushes. Replace brush set

if brushes are less than 3/16 in (5 mm) long.

b. Rotor - Inspect for stripped threads, scuffed

pole piece fingers or damaged bearing sur-

faces (because of bearing turning on shaft).

b

c

c. Rotor Slip Rings - Clean slip rings with 400

grain (or finer) polishing cloth. Blow off dust

with compressed air. Inspect slip rings for

grooves, pits, flat spots or out-of-round [.002

in. (.05 mm) maximum]. Replace if defective.

a

d. Rotor Shaft Bearings - Inspect for damaged

seals, lack of lubrication, discoloration (from

overheating) or excessive side or end play.

Hold inner race of bearings while turning out-

er race. Bearing should turn freely without

binding or evidence of rough spots.

73093

a - Front Housing

b - Bearing Driver

c - Bearing

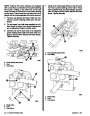

e. Stator - Inspect for damaged insulation or

wires; also inspect insulating enamel for heat

discoloration, as this is usually a sign of a

shorted or grounded winding or a shorted

diode.

Installation

1.

Using an arbor press, press on outer race of new

bearing until fully seated in housing.

f.

Regulator - Inspect leads for damaged insu-

lation.

g. Front and Rear Housings - Inspect for

cracks, distortion, stripped threads or wear in

bearing bore (from bearing outer race spin-

ning in bore). Replace if defective.

h. Fan - Inspect for cracked or bent fins, broken

welds or worn mounting hole (from fan spin-

ning on shaft).

i.

Pulley - Inspect pulley mounting bore and for

wear. Inspect drive surface of pulley sheaves

for trueness, excessive wear, or corrosion.

Repair damaged surfaces, if possible, with a

fine file and a wire brush, or replace pulley.

Drive surfaces must be true and smooth, or

drive belt wear will be greatly accelerated.

73094

2.

Install snap ring to retain bearing.

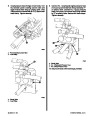

j.

Alternator - If alternator has output at low

speeds, but no output at high speeds, rotor

field winding may be shorting or grounding

out because of centrifugal force. Replace ro-

tor, if all other electrical components test

good.

Index

90-823224--2 796

CHARGING SYSTEM - 4C-29

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you