ENGINE MOUNT ADJUSTMENT WAS

DISTURBED DURING SERVICE

IMPORTANT: Be sure that boat does not move

once reading has been taken from input shaft

flange, as this reading establishes a reference

point for aligning drive shaft and engine follow-

ing. If boat is moved, reference point may be al-

tered and subsequently,improperdriveshaftand

engine alignment may occur. Alignment tool

MUST BE in place during entire alignment proce-

dure if drive unit is not installed.

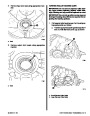

NOTE: A Universal Protractor is recommended for

measuring the angles in the following steps.

IMPORTANT: In the following steps, the protrac-

tor readings will be taken off of vertical and hori-

zontal surfaces; therefore, both the 0 degree and

the 90 degree marks will be used. It should be

kept in mind that these are reference marks only

and the assigned numbers should be ignored. It

is only necessary to determine the number of de-

grees and to which side (left or right) of the refer-

ence marks the indicator needle rests. PRO-

TRACTOR MUST BE VIEWED FROM THE SAME

SIDE OF POWER PACKAGE THROUGHOUT IN-

STALLATION.

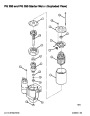

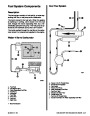

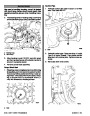

a

b

a

c

72592

a

a - Indicator Shaft Flange

b - Protractor

c - Indicator Needle

NOTE: For ease of installation we recommend the

use of a chain leveler in the following steps.

72429

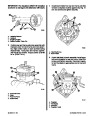

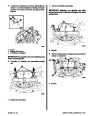

3.

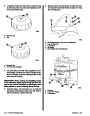

Adjust engine mounts so that an equal amount of

up and down adjustment exists.

a - Reference Marks

4.

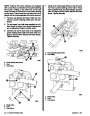

Attach a suitable lifting chain to lifting eyes on en-

gine and adjust so that engine will be level when

suspended, then place engine into its approxi-

mate position (in boat) using an overhead hoist.

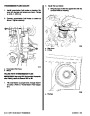

1.

2.

Refer to Section 8E - “Drive Shaft Models/Propel-

ler Shaft,” and remove drive shaft.

Position base of protractor against input shaft

flange, as shown. NOTE and RECORD the num-

ber of degrees and to which side of the reference

mark the indicator needle has moved in the fol-

lowing chart.

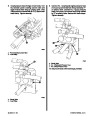

5.

Refer to Section 8E - “Drive Shaft Models/Propel-

ler Shaft,” and install drive shaft while observing

precautions in Section 8D, especially about

aligning gimbal bearing U-joint centerlines with

extension drive shaft U-joint centerlines at bear-

ing support input shaft. DO NOT install shields at

this time.

Reading from Step 1. __________ degrees to the

_________

side of reference mark.

Index

2B-6 - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSIONS

90-823224--2 796

Product Specification

| Categories | Mercury MerCruiser Manuals |

|---|---|

| Tags | Mercury MerCruiser 454 CID, Mercury MerCruiser 502 CID |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

Hugely helpful service manual! Perfect. Thank you!

Manuals are all Important for Technician

This book is invaluable if you do your own repairs. Great book.

Could not find a copy until a search brought me here.

Excellent print.

Thank you