X INSTALLATION

PROPELLER SERVICE

Install new cotter pin and bend ends to se-

cure.

Remove block of wood. Make sure engine is

in NEUTRAL; give propeller a spin. It must

turn freely.

Propeller Selection

WARNING

Repair

Be alert of people in the water. Always

shift the outboard to NEUTRAL and

shut off the engine immediately when

your boat is in an area where there

might be people in the water. Serious

injury or death can result from contact-

ing a rotating propeller or moving boat

and outboard.

If your propeller hits a solid object, the impact

is partially absorbed by the rubber bushing in

the hub to help prevent damage to the out-

board. A strong impact can damage the hub

and propeller blades. Damage to blades can

cause unusual and excessive vibration. Dam-

age to the hub can cause excessive engine

RPM with little forward movement.

To select the correct propeller for your boating

application, your boat and outboard MUST be IMPORTANT: Avoid or limit operation using a

damaged propeller. Carry a spare propeller.

water tested.

Keep your propeller in good condition. Use a

file to smooth slight damage to blade edges.

IMPORTANT: The correct propeller for your

boat, under normal load conditions, will allow

the engine to run near the midpoint of the

RPM operating range at full throttle. Refer to

Specifications on page 38.

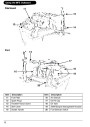

IMPELLER SERVICE, MJRL

Removal

WARNING

Use a 3/16 Ballhex driver to remove the six

impeller housing screws. Remove the impel-

ler housing.

When servicing the propeller, always

shift the outboard to NEUTRAL posi-

tion, turn the key switch OFF, and twist

and remove all spark plug wires so the

outboard cannot be started acciden-

tally.

IMPORTANT: Apply Triple-Guard grease to

the entire propeller shaft before installing the

propeller. At least annually, remove the pro-

peller and check for debris. Clean the shaft

and regrease it before reinstalling a propeller.

Installation

Slide thrust washer onto shaft with shoulder

facing aft.

Slide propeller onto shaft, engaging the

splines and seating it on the thrust bushing.

Slide spacer onto the shaft and engage the

propeller shaft splines.

Wedge a block of wood between the propeller

blade and the anti-ventilation plate.

Install propeller nut and tighten to a torque of

120-144

in. lbs. (13.6-16.3 N·m).

Install keeper on propeller nut, align keeper

slots and cotter pin hole.

41

| Categories | BRP Brand Manuals, Evinrude Brand Manuals, Evinrude MFE Manual, Evinrude Outboard Manual |

|---|---|

| Document Type | Boat Motor Manual. Marine Operator's Engine Guide. |

| Tags | Evinrude 55 hp, Evinrude MJRL, Evinrude MRL |

| Model Year | 2009 |

| Download File |

|

| Document File Type | |

| Publisher | evinrude.com |

| Wikipedia's Page | Evinrude Outboard Motors |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)